HIGH PRECISION TOOL & MOULD MAKING

Precision Toolmaking

Alpha Precision have over twenty years’ experience manufacturing precision moulds for the Medical Device, Automotive and Aerospace industries.

We are constantly pushing the boundaries when it comes to toolmaking and have built a reputation as technical toolmakers. We love a challenge, and we pride ourselves on delivering innovative solutions to complex problems. Our team are highly experienced in designing and manufacturing tools for technically challenging, tight tolerance parts that perform in highly regulated production environments. We have experience with a wide variety of metals, plastics and rubbers.

When you partner with Alpha Precision, you are collaborating with premium toolmakers, who specialise in complex toolmaking.

Our early involvement in the Design for Manufacture (DFM) stage allows us to make critical decisions during the manufacturing process to ensure the manufacturability of each mould. Resulting in a high precision, high performance, high quality, premium commercially viable tool.

Alpha Precision

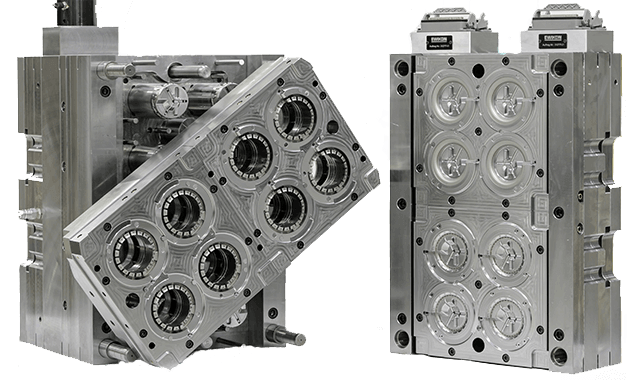

Toolmaking Capabilities

- Injection Moulds

-

- Prototype Soft Tooling

- Pilot / Pre-Serial (Hardened)

- Overmould Tools

- Multi Shot Mould Tools

- Unscrewing Mould Tools

- High Cavitation Mould Tools (up to 32 cavities)

- LSR/ Rubber Cold Runner Moulds

- Press Tooling: – Single Stage – Strip Progression

- Thermo Forming Tools: – Blow Moulds

- Fixtures

- Metrology/Inspection Fixtures

- Special Purpose Fixtures

- Robot Fixtures & Tooling

- Precision Machine Parts

- Small/Medium Batch

- Precision: – Milling & Turning

- Wire EDM

Alpha Precisions Toolmaking Process

Alpha Precision provides technical leadership and expertise at each stage of the design process.

1. Design

We collaborate with our customers and establish the project scope.

2. Prototype

Once we have completed the designs, we progress to prototyping. Which is fully supported with our in house testing facilities.

3. Build

Once we are happy that prototype is fit for purpose, we begin building the serial production tooling.

4. Test

We conduct stringent testing on the tooling to ensure its fit for purpose.

5. Support

We provide an unrivalled level of support to our clients at all stages of a project, from design analysis all the way through to mould validation and mould maintenance.

Mould Maintenance, Repair and Refurbishment

Mould maintenance is an essential step in the moulding process to ensure a mould is running at optimal performance.

Mould maintenance is an essential step in the moulding process to ensure a mould is running at optimal performance. The moulding process causes wear and tear on moulds over time, and if left unchecked can lead to defects and costly downtime. Alpha Precision offer a regular maintenance service which is specific to each injection mould, ensuring your mould is running effectively.

Alpha Precision have the knowledge and skills to troubleshoot any issues with a mould. Our extensive knowledge in tool functionality allows us to easily suggest new materials and techniques that will improve the functionality and efficiency of the mould.

Our refurbishing team are specialist in mould disassembly, decontamination and restoration.

Mould Maintenance, Repair and Refurbishment

Mould maintenance is an essential step in the moulding process to ensure a mould is running at optimal performance.

Mould maintenance is an essential step in the moulding process to ensure a mould is running at optimal performance. The moulding process causes wear and tear on moulds over time, and if left unchecked can lead to defects and costly repairs & downtime. Alpha Precision offer a regular maintenance service which is specific to each injection mould, ensuring your mould is running effectively.

Alpha Precision have the knowledge and skills to troubleshoot any issues with a mould. Our extensive knowledge in tool functionality allows us to easily suggest new materials and techniques that will improve the performance and efficiency of the mould.

Our refurbishing team are specialists in mould disassembly, decontamination and restoration.

We welcome new challenges.

Talk to us today to discuss your next precision engineering project.