PRECISION DESIGN

Precision Design

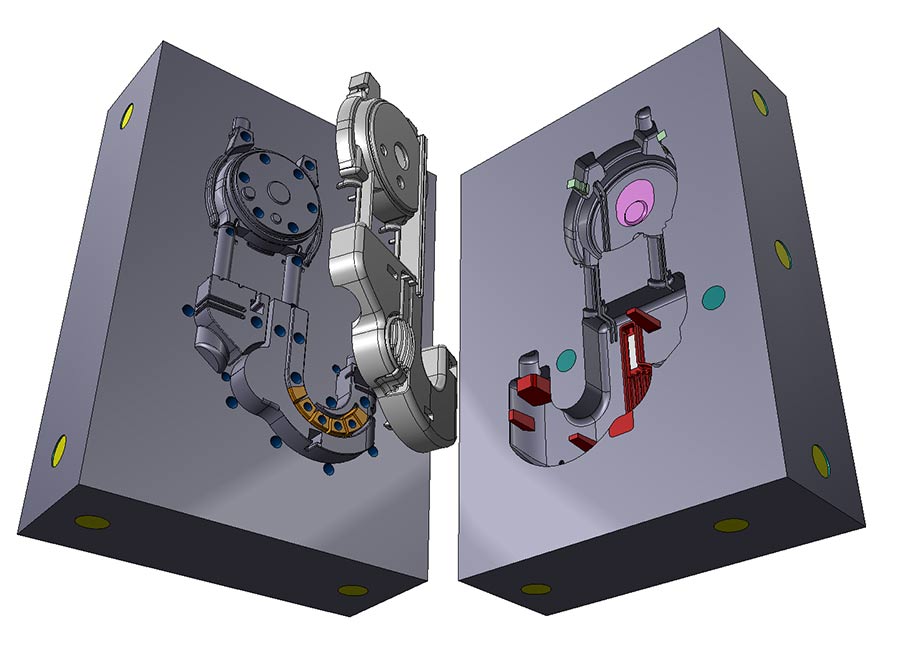

Alpha precision has over twenty years’ experience designing moulds and precision parts for clients in the Medical Device, Automotive and Aerospace industries. Our experienced design team utilise leading 2D and 3D CAD design software to design complex moulds. We partner with our clients from their initial concepts, right through to the final production.

Alpha Precision’s

Design Process

Alpha Precision provides technical leadership and expertise at each stage of the design process.

1. Analysis

The first step in our design process is to conduct an in-depth analysis to identify your requirements and how Alpha Precision can add value to your process.

2. Design

Our designers work closely with your engineers to ensure the design is optimised for manufacturing. We provide expert advice on Design for Manufacturing (DFM), materials, processes and tolerances.

3. Prototyping

Once we have completed the designs, we quickly move into prototyping. We have the facilities in house to test prototypes as required.

4. Production

Once you are happy with the prototype, we can quickly move the process to the manufacture of the serial production tooling.

Innovative Designs

Over the years we have established a reputation as complex tool and mould designers. We love a challenge and excel in delivering complex design solutions to our clients. Through collaboration with our clients in the early stages of product design, we help them develop products that are robust, reliable, and commercially viable.

Design for Manufacture (DFM)

Alpha Precision implements a DFM methodology which allows us to take a holistic approach to your project. Through our DFM process we aim to optimise your entire process, saving time and eliminating the risk of product failure.

Our design team will work closely with you to gain a deep understanding of your product concept and technical requirements. We are committed to ensuring your concept is optimised to ensure efficient manufacturing.

Design for Manufacture (DFM)

Alpha Precision implements a DFM methodology which allows us to take a holistic approach to your project. Through our DFM process we aim to optimise your entire process, saving time and eliminating the risk of product failure.

Our design team will work closely with you to gain a deep understanding of your product concept and technical requirements. We are committed to ensuring your concept is optimised to ensure efficient manufacturing.

The key to a successful project is the involvement of the Alpha Precision team in the early stages of product design. This allows for the early identification of problems using FEA software, preventing costly issues later in the project. We utilise the best technology in the market for 3D design and part/mould tool analysis software. Our technology and expertise in a wide range of materials allows us to get your concepts into production as fast and efficiently as possible, reducing time to market while maximising cost savings.

Alpha Precision

Design Capabilities

- Over twenty years Engineering expertise

- Knowledge of industry quality systems

- Leading 2D and 3D CAD design software

- Integrated CAD and CAM used throughout the process

- DFM; part to mould optimisation

- Mould Flow plastic part analysis

- R & D, prototyping tooling design

- Serial, production tooling design

- Gauge, fixture & robot tooling design

- Industry recognised project management software

- Online project management systems

- Full ERP management system for complete traceability

We welcome new challenges.

Talk to us today to discuss your next precision engineering project.