MANUFACTURING

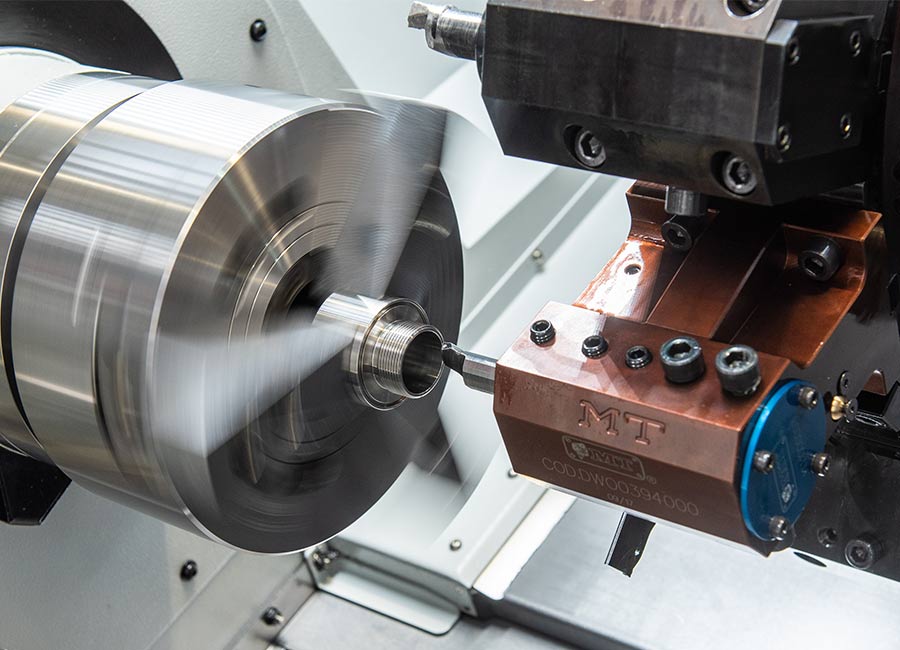

Precision Manufacturing

Alpha Precision are experts in the manufacture of low to medium volume precision engineering components for the Medical Device, Automotive and Aerospace Industries. Our highly skilled team is committed to delivering a manufacturing process that is fully controlled and managed to meet the quality standards and tolerances expected by our customers.

Alpha Precision

Machining Capabilities

- CNC Milling

We have a range of CNC milling machines which allow us to machine low to medium volume parts. - CNC Turning

We have the capabilities to machine parts from a wide variety of materials, including plastics, metal and rubber.

- Precision Grinding Features

Our precision grinding capabilities allow us to maximise surface quality, high rates of throughput, fast cycle times and precision finishes.

- CNC EDM Spark Eroding

Our spark eroding capabilities allow us to machine complex details to tight tolerances in a range of materials. - CNC EDM Wire Erosion

We offer a comprehensive wire erosion service for complex components. - Integrated CAM Process

Our integrated CAM process allows us to provide greater accuracy and consistency, leading to a smarter connection between applications.

Alpha Precision CNC Machines

Our comprehensive range of CNC machines enables us to provide innovative solutions to complex machining challenges.

We have invested heavily in the most technologically advanced machinery which ensures a right-first-time approach to all our manufacturing methods. Our latest CNC machinery includes:

- Roeders Hsm 42K Spindle

- Makino F3 Hsm 25k Spindle

- Makino F5 Hsm 25K Spindle

- Hardinge Conquest H51

- CNC CMM Vision System

All of our machinery is regularly maintained by our in-house engineers.

We welcome new challenges.

Talk to us today to discuss your next precision engineering project.