QUALITY

Quality Control

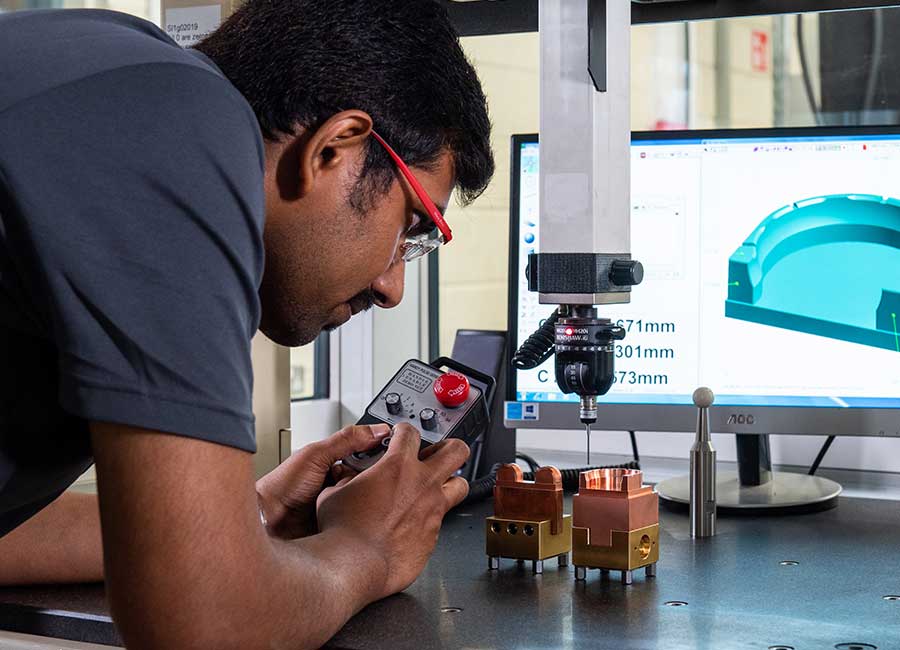

Alpha Precision have a fully integrated quality assurance system which forms the backbone of all our processes, from initial support all the way through to manufacturing. We have a proven track record of providing a right first time, high-quality service to our customer and ensure the highest quality standards are met throughout the duration of a project.

Alpha Precision is an ISO 9001: 2015 and ISO 13485 approved company and we are committed to maintaining high-quality standards across all areas of the company. We are continually upskilling our employees through internal and external training. Our highly skilled team of toolmakers and designers are trained to the highest standards and we aim to provide services which meet and exceed our customers’ expectations.

Our quality assurance system allows us to offer:

- Full traceability from stock to finished components

- Reduction in time from FOIR to final part approval

- Efficient identification and solution of quality issues

- Integration of short production runs with mould build reduces time to market

- In-house CMM capabilities to produce detailed dimensional reports

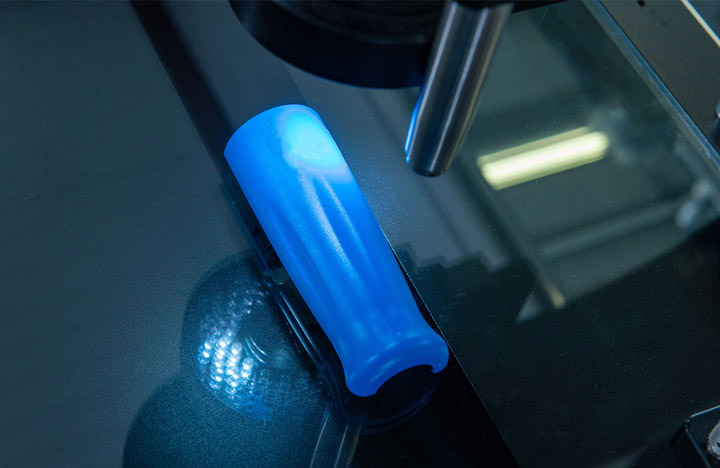

From our thermally controlled toolroom environment. We are constantly pushing the boundaries when it comes to tight tolerances and materials and have the ability to produce precision parts and moulds of the highest quality in a wide range of materials, including plastics, metals, and rubber.

We welcome new challenges.

Talk to us today to discuss your next precision engineering project.